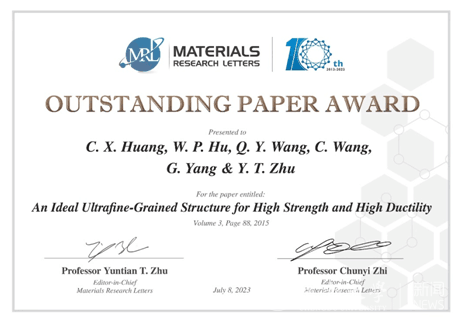

The Materials Research Letters (MRL) selected a series of outstanding papers on the occasion of its 10th anniversary. The paper "An Ideal Ultrafine-Grained Structure for High Strength and High Ductility" by the team led by Prof. Wang Qingyuan of Chengdu University (CDU) won the 2013-2023 MRL Outstanding Paper Award, as recognition for the team's contribution to the field of ultrafine-grained metal structure materials.

Ultrafine-grained (UFG) metals and alloys are strong and tough structures with ultrafine grains, which is an important means to manufacture advanced high-performance metallic structural materials. The widely used method for preparing UFG structural materials is a severe plastic deformation technique, which subdivides grains through the extremely large plastic strain of metal to realize dislocation rearrangement and grain subdivision. It has the advantage of low-cost mass production to meet realistic structural engineering applications. However, a high density of dislocations often exists in the as-processed UFG metals, which leaves little room for further dislocation accumulation and low strain hardening and ductility. Annealing UFG metals to lower dislocation density can recover some of the ductility, but often at the cost of a significant reduction in strength. In addition, some dislocation structures produced by severe plastic deformation (SPD) could be relatively stable and hard to be fully annealed out without significant grain growth, which dramatically decreases the strength. To this end, the researchers from Prof. Wang's team reported an ideal UFG microstructure in 304 L austenitic stainless steel (304 L SS) that was produced by reverse transformation of deformation-induced martensite. This UFG microstructure is composed of fine grains and high-density twins to ensure high strength, while its low dislocation density leaves more room for strain hardening. Besides, the low stacking fault energy (SFE) of 304 L SS leads to the simultaneous accumulation of both dislocations and stacking faults (SFs), making it more effective in strain hardening. As a result, a combination of high yield strength (810 MPa) and high uniform elongation (30%) is obtained in tensile tests. This brings new ideas for the approach of producing ideal UFG microstructure materials with face-centered cubic metals and low stacking fault energy.

MRL is an international academic journal focusing on the frontier of materials science research. Founded in 2013, MRL is published and distributed by Taylor & Francis, an internationally renowned publisher. Its editorial office is set up at Nanjing University of Science & Technology, with Prof. Yuntian T. Zhu of the City University of Hong Kong and Prof. Quanxi Jia of the University at Buffalo serving as Editors-in-Chief. MRL provides fast communications on cutting-edge materials research findings, with a focus on updates, literature reviews, and prospects in metallurgical engineering, material engineering and technology, energy materials, material physics and chemistry, new functional materials, and other fields. The journal is indexed in Science Citation Index Expanded (SCIE), Scopus, Directory of Open Access Journals (DOAJ), and CAS Source Index (CASSI). Its most recent impact factor (IF) stands at 8.516, while the latest CiteScore is 13.6.

Paper link: https://doi.org/10.1080/21663831.2014.968680